| Filling Product | Liquid & Paste |

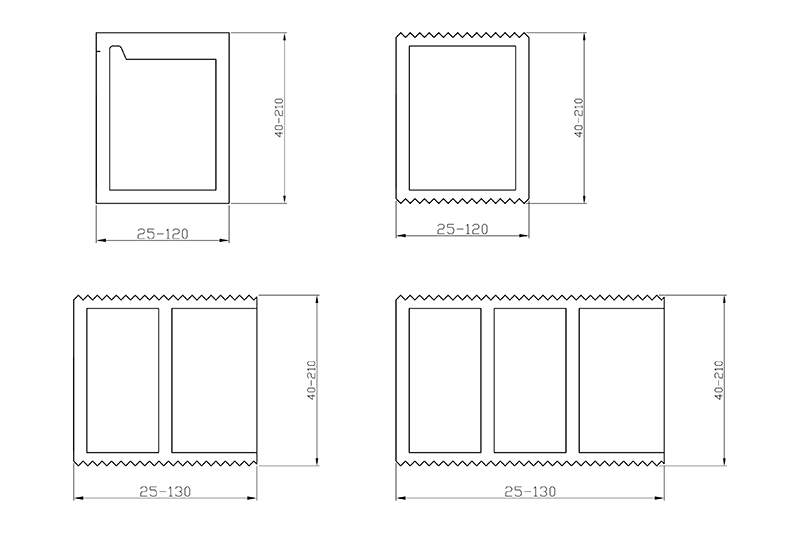

| Pouch Pattern | 3-side seal & 4-side seal |

| Pouch Height Range |

2divisions

120-210mm 3divisions 80-150mm 4divisions 60-120mm 6divisions 40-75mm According to the width of horizontal sealing pouch height range is different. |

| Pouch Width | 25-130mm |

| Packaging Capacity |

20-200

pouches per minute (depending on pouch height,film composition,product property,etc) |

| Filling Capacity |

1-100ml (depending on product property and filling device to be used) |

| Applicable Film Width | 50-260mm |

| Maximum Film Roll Dia | ¢400mm |

| Power Consumption | 3-phase 380V 6kw |

| Air Consumption | |

| Machine Dimensions | 1304mm(L)×1195mm(W)×2128mm(H) |

| Machine Weight | Approx.670kg |